Design, Manufacture & Installation

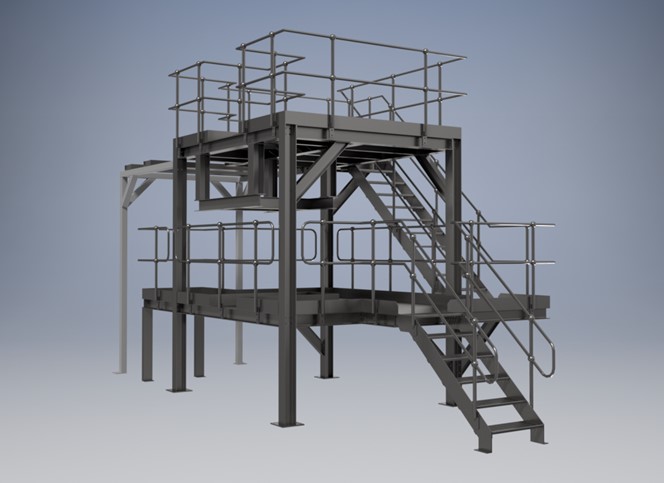

Tinsley Bridge have completed an order to design, manufacture and install new platforms to support the powder metals process at Liberty Powder Metals in Middlesbrough.

All steelwork was manufactured in accordance with BS EN 1090-2:2018 to Execution Class 2. Following manufacture, items were hot dip galvanised in accordance with BS EN 1461:2011 and trial assembled in-house at Tinsley Bridge. The assembly was then stripped into sub-assemblies before delivery to site, followed by site installation by Tinsley Bridge’s own site installation team.

David Brough, Project Engineer, said “The design process involved regular reviews with our customer to ensure functional requirements were met. This created additional challenges in the current social distanced environment, but screen sharing using Microsoft Teams is a very powerful tool. The final design and calculations were verified against Eurocodes by third party consultant prior to manufacture”.

The design was in accordance with the following standards:

Supporting structure in accordance with relevant parts of Eurocodes:

EN 1990:2002/A1:2005 – Eurocode – Basis of structural design

EN 1991-1-1:2002 – Eurocode 1: Actions on structures – Part 1-1: General actions – Densities, self-weight, imposed loads for buildings

EN 1993-1-1:2005 – Eurocode 3: Design of steel structures – Part 1-1: General rules and rules for buildings

EN 1993-1-8:2005 – Eurocode 3: Design of steel structures – Part 1-8: Design of joints

Design of Stairs, Landings and Handrails in accordance with:

BS EN 14122-2:2016 -Safety of machinery — Permanent means of access to Machinery Part 2: Working platforms and walkways

BS EN 14122-3:2016 – Safety of machinery — Permanent means of access to Machinery Part 3: Stairs, stepladders and guard-rails