Fabrication and Welding

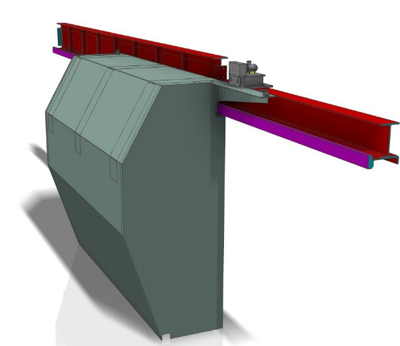

Medium and heavy metal fabrication requires flexibility, versatility and large-scale engineering knowhow. With our extensive fabrication and welding facilities and highly skilled and experienced staff we can manufacture products for a multitude of applications across a broad range of industries.

Tinsley Bridge offer a complete, integrated range of fabrication and welding solutions which can cover the entire planning and manufacturing process from concept to final commissioning.

Our team of experienced fully coded welders, fabricators and site installation engineers with an extensive depth of expert knowledge in key industrial sectors work around the country on various steelwork projects.

Accredited with the highest quality standard available

We bring a professional approach to ensure projects are delivered on time, on budget and quality assured, whatever the size. We are accredited with the highest quality standard available for fabrication, namely BS EN 1090-2 Execution Class 4, and BS EN 3834.

We have large scale, well resourced factory workshops to support the manufacture and trial-build of heavy fabricated equipment and operational testing prior to dispatch.

Metal Fabrication and Welding Capabilities

- Hot and cold metal forming

- Coded welders to ASME IX

- Straightening

- Auto cold sawing

- Plate folders

- Guillotines

- Rolling

- Shearing

- Punching

- Open die and upset forging

- Heat treatment

- Precision forging

- Banding and forming

- Stainless steel fabrication

- MIG and TIG welding

Case Studies

Click on our case studies below to find out more information.

Demanding Offshore Engineering Project Completed

Lobster Back Completed for Liberty Steel

Structures for Smart Media Displays

Innovative Resolve for Sticking Door Problem

New Bridge for Canal & River Site Trust

Grade 1 Nuclear Project Completed

Roof Components for Wimbledon No.1 Court

Safety Critical Parts for London Underground