Lean Manufacture Delivers Business Excellence

Tinsley Bridge have collaborated with the Confederation of British Metalforming (CBM) in an approach using Lean Manufacturing to improve operational performance.

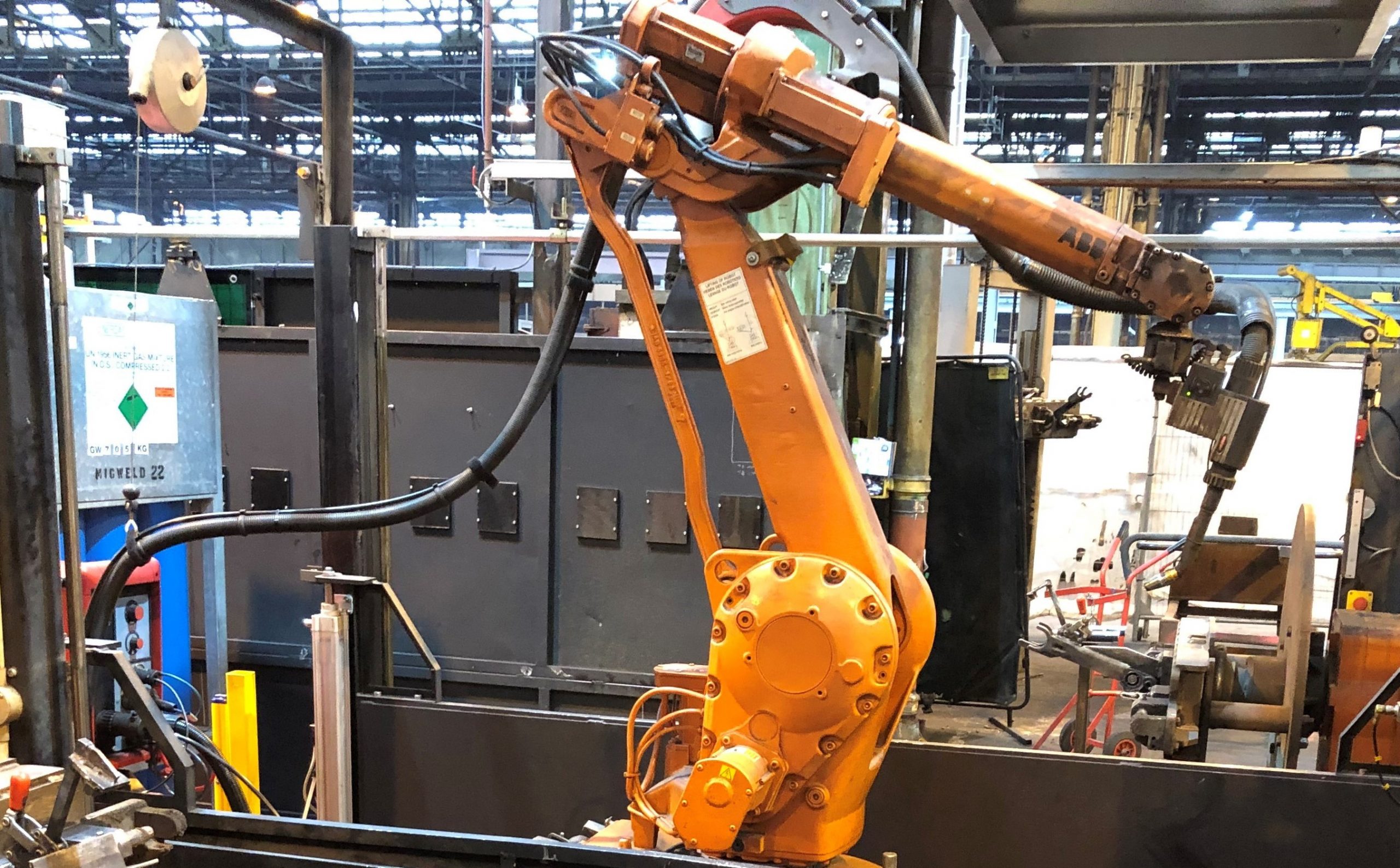

The CBM’s expert consultancy were engaged to help improve the productivity of a robot weld cell that manufactures truck stabiliser bars for European automotive OEMs.

In order to satisfy the high levels of customer demand the robot cell was being supported by a manual welding operation. This added unplanned costs and constrained the ability to take on new business. A cross-functional team was assembled to work with the CBM experts. Over the course of several sessions an improvement plan was developed and implemented. This introduced a new lean operating standard for the cell which enabled the demand to be fulfilled without the additional manual process, together with improved daily and weekly TPM (Total Productive Maintenance) checks.

Subsequent progress has been achieved building on these improvements, monitoring progress through new KPIs and regular team review meetings. All operators completed training to the new lean standard which has resulted in significant increases in output whilst the heightened TPM standards have reduced technical downtime too.

Russell Crow, Tinsley’s Engineering Director, said “The CBM support had a big impact on performance. The lean project has given us confidence to add work to the cell and experience to apply a similar structured approach elsewhere in the business.”