Site Installation, Erection & Testing

Qualified engineers and a team of experienced fabricators and site installation engineers with an extensive depth of expert knowledge in key industrial sectors work around the country on various steelwork projects. They can project manage small, large or complex developments and bring a professional approach to ensure projects are delivered on time, on budget and quality assured, whatever the size.

We have worked successfully on a number of major on-site installation, assembly and commission projects across a number of sectors. As well as offering a machine move and site erection service we also provide on-site repair, modification and maintenance.

Click here to find out more about our site installation projects.

OUR OTHER SITE SERVICES:

- Project engineering, including assembly and pre-delivery commissioning

- Contracted maintenance for power, steel and other industrial process sites

- Inspection & certification

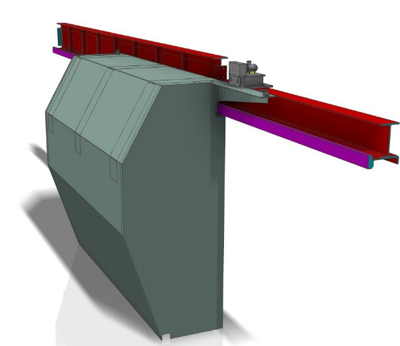

- Design, manufacture & installation of structural steel, large tanks and bundings

- Specialists in working at height

- Supply of high level access equipment

- Turn key solutions include hydraulic, pneumatic and control systems

Highly qualified skilled fitters

Our team of highly qualified skilled fitters have vast experience in undertaking complex assembly work across a number of sectors. This includes strip down and reassembly of new and used equipment of varying sizes and complexities.

We undertake anything from bench fitting work to large scale assembly work of components weighing up to 60 tonnes. Predominantly specialising in the strip, rebuild and testing of mechanical and hydraulic equipment, we offer full turnkey solutions to our customers, and we pride ourselves on providing exceptional quality and flexibility on all the projects we undertake.

We have experience and the capability to provide the following services:

- Strip and rebuild gearboxes

- Fault finding services

- Replacement bearings

- Changing seals

- Dismount couplings

- Fit keys (taper and parallel)

- Injection mounting

- Contact marking setting

- Calibration / condition monitoring of equipment

- Pressure testing

- Flow rate testing

- Load testing

- Drilling, tapping and inspection

- NDT and factory acceptance testing

Support Services

Our support services include embedded engineers and technicians for tier 1 manufacturers and utilities, contracted maintenance for power, steel and other industrial processes. We also carry out inspection & certification and are specialists in working at height, as well as supplying high level access equipment and delivering training and safe operating procedure programmes.

Case Studies

Click on our case studies below to find out more information.

Roof Components for Wimbledon No.1 Court

New Bridge for Canal & River Site Trust

Rail Engineer Features Tinsley Bridge

Grade 1 Nuclear Project Completed

Lobster Back Completed for Liberty Steel