Tyzack Apprentice Trained Talent Push the Boundaries!

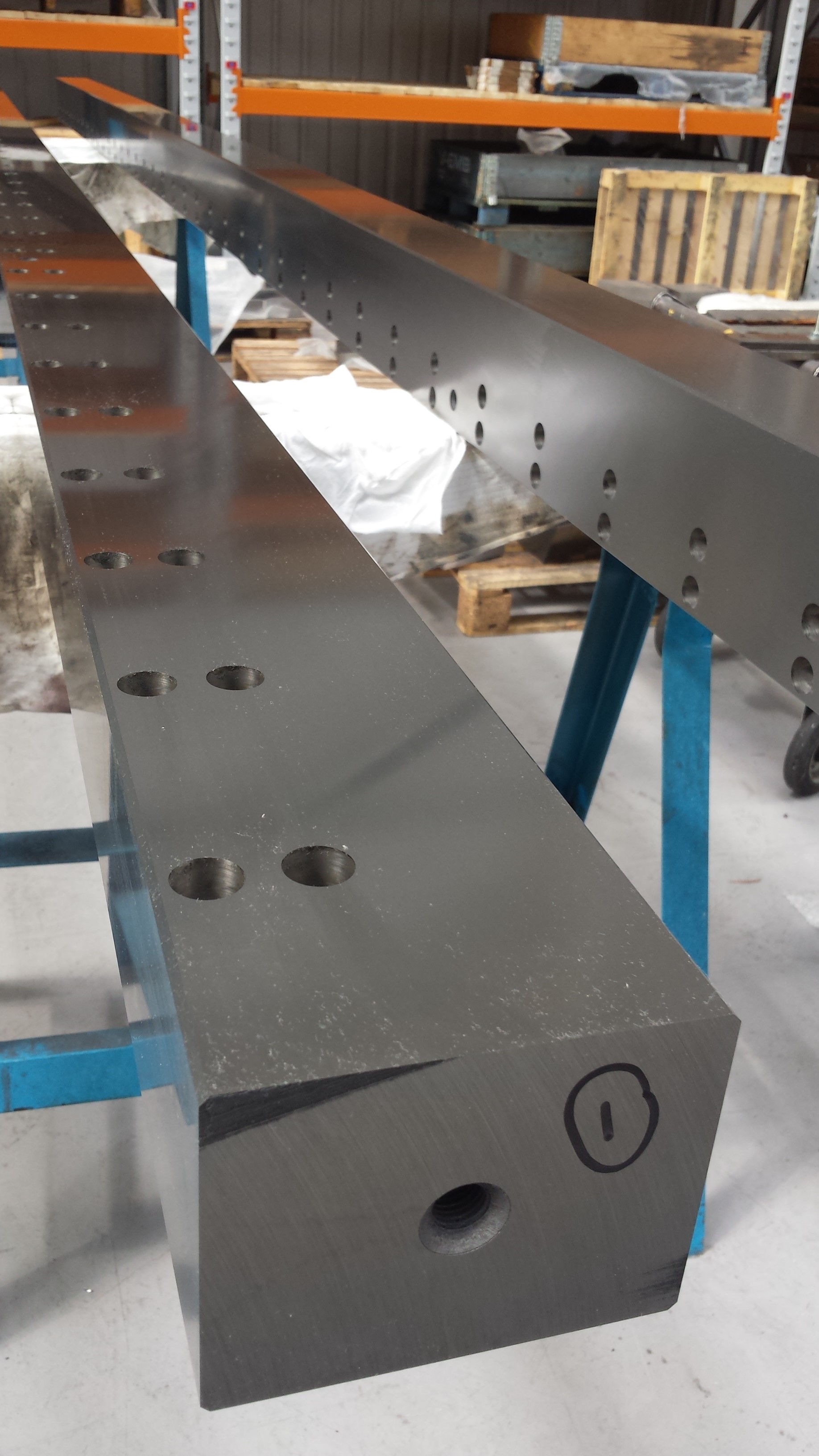

Tyzack Machine Knives have this month manufactured the longest ever single piece slideway. Tyzack slideways as designed for the specialist precision machine tool industry operating to extreme accuracies.

The fundamental accuracy level of any machine tool is defined by the slideways, requiring exceptional engineering skill to achieve the specified tolerances. Parallelism, squareness and flatness levels are all within a few microns, less than a quarter of the thickness of a human hair. Even more remarkable considering each slideway is 5m long and weighs nearly ½ tonne!

Paul Barkas, General Manager said “Qualified apprentices Dale Batey, Sam Bishop, Brad Fontana and Gary Tandy all played a major role in this project and trained through the Tyzack scheme. It’s great they are now able to use their skills and experience to manufacture parts which are only possible due to the engineering excellence embedded in Tyzack. Sheffield is a city a city globally renowned for its steel heritage, manufacturing excellence and technically skilled workforce. With our commitment to training new talent and a £4m investment in state of the art factory facilities, Tyzack are well positioned to ensure Sheffield’s legacy of advanced manufacturing excellence will continue and benefit new a generation”.

The slideways were manufactured for Cranfield Precision, a builder of precision optical grinding machines.